3 Great Uses for a Metal Disintegrator

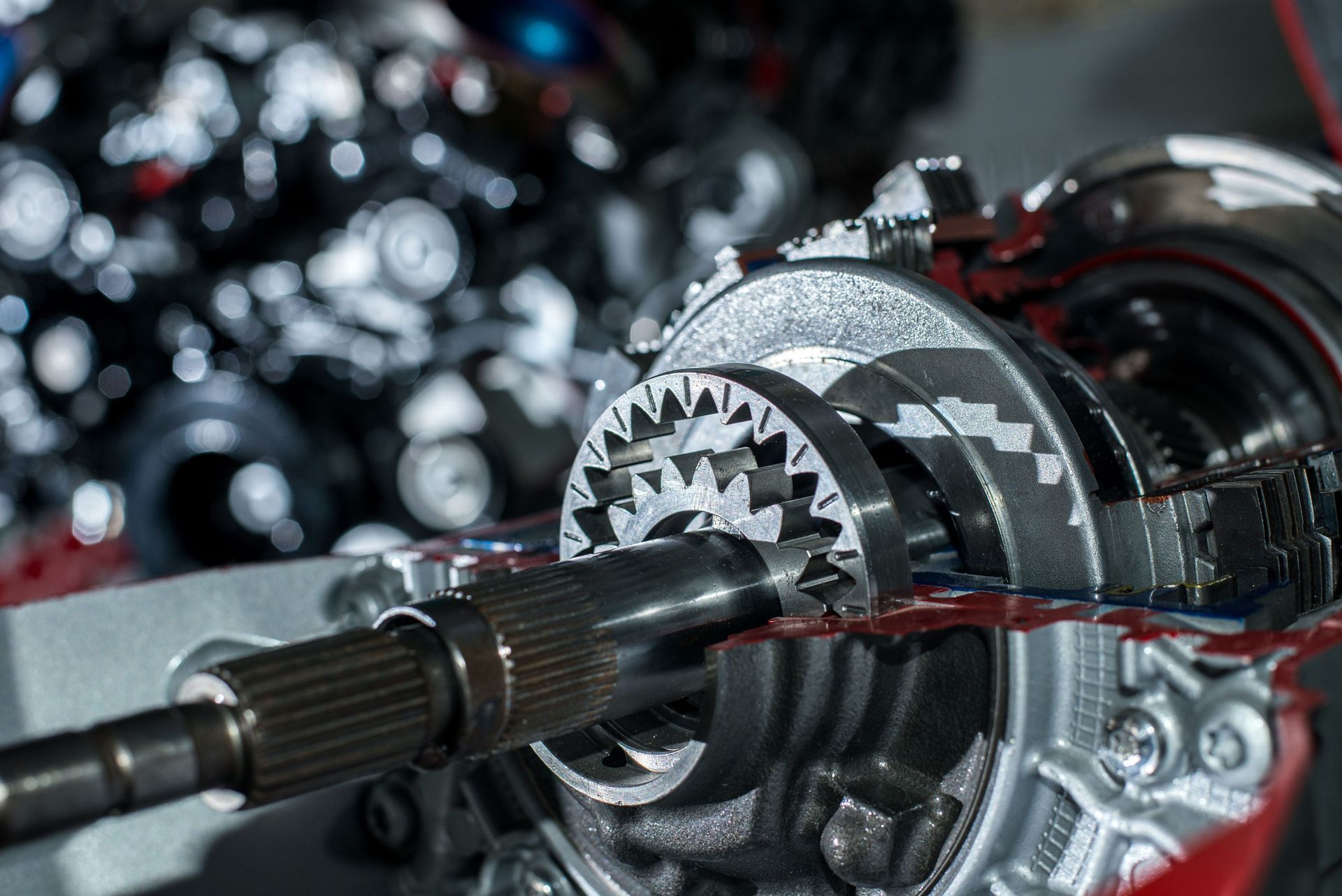

Metal disintegrators have become essential tools in various industries due to their ability to efficiently handle critical tasks. These machines, designed to remove broken tools or studs from workpieces without damaging the surrounding material, offer incredible utility across different sectors. In this blog post, we'll explore the best uses for a metal disintegrator and shed light on why they have become indispensable in modern manufacturing and repair processes.

1. Provide Method to Remove Taps and Drills

One primary application of metal disintegrators is in the realm of machine shops. With over 16,244 machine shop businesses in the U.S., according to IBISWorld, the need for efficient tool removal and repair is ever-present. Metal disintegrators provide a non-destructive method to remove broken taps, drills, or bolts from parts, saving time and resources that would otherwise be spent in re-manufacturing or remachining parts. For any shop aiming to maintain excellence in productivity, a metal disintegrator is a crucial addition to their toolkit.

2. Provide Precision and Safety

Apart from machine shops, metal disintegrators are highly valuable in the aerospace industry, where precision and safety are of paramount importance. Landsdide incidents, crashes, or regular wear and tear can result in broken components deep within aircraft machinery. Using a metal disintegrator, aerospace technicians can precisely remove these damaged tool fragments without compromising the integrity of the rest of the parts. This capability is vital to maintaining the stringent safety standards required in the aerospace field while ensuring uninterrupted service and operation.

3. Clear Obstructions and Repair Equipment

Another significant area where metal disintegrators shine is in the energy sector, particularly in oil and gas operations. Equipment in this industry often undergoes extreme stress and encounters numerous challenges that can result in snapped components. By employing metal disintegrators, maintenance teams can efficiently clear obstructions and repair equipment on-site, reducing downtime and maintaining continuous energy production. This application not only boosts operational efficiency but also ensures that energy companies can reliably meet demand without costly interruptions.

The versatile utility of metal disintegrators makes them an essential tool in many industries. Whether you're working in a massive machine shop, the high-stakes aerospace field, or the demanding energy sector, these machines offer precision and efficiency unparalleled by other methods. By integrating metal disintegrators into regular operations, businesses can significantly cut down on resource waste, improve turnaround times, and maintain superior productivity and safety standards. If you're looking for metal disintegrators, contact Electro Arc today.

Share On: