Why are Metal Disintegrators Sometimes Called Spark Eroders?

Spark erosion is the process of vaporizing metal using a high-frequency spark discharge. Metal disintegrators are a subcategory of EDM, which is often referred to as Spark Erosion. Metal Disintegration Machining (MDM) is the process that Electro Arc machines use. These machines are specifically used to remove broken bolts, taps, pins, screws etc. quickly

"Spark Erosion" Applications:

Electro Arc Patented the Metal Disintegrator in 1942

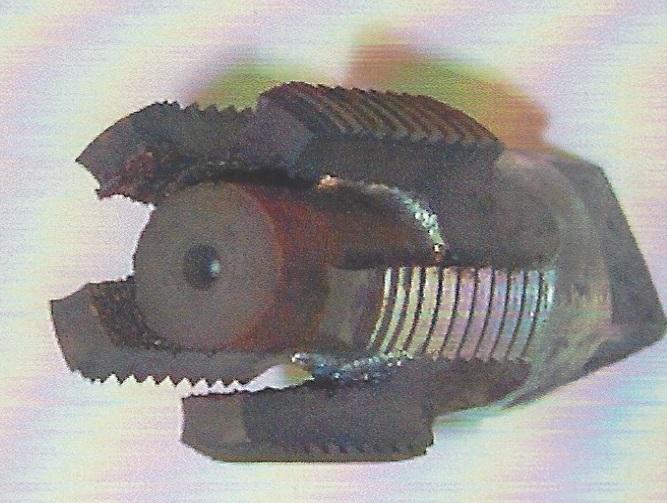

If you are dealing with a broken screw, broken bolt, broken drill, or other broken tooling on a regular basis, you may have used a metal disintegrator to remove them. Metal disintegrators are specialized EDM machines originally patented in 1942 by Electro Arc. This broken bolt removal tool is essential in industries such as power generation, off-road vehicles, mining, aircraft repair, and automotive repair.

Remove your Broken Tooling wwth Metal Disintegration Machining

Spark eroders use the process of spark erosion, also referred to as spark machining, or die sinking to remove material from a part with electrical discharges. This modern machining process is responsible for many of the manufactured processes that exist today. Electrical discharge machining (EDM) has a long history which has led to significant breakthroughs in technology. While EDM has a variety of applications, MDM has the targeted ability to remove broken bolts, broken pins, broken drills, and other broken tooling in minutes. Although metal disintegrators are in a sub-category of Electrical Discharge Machining called Metal Disintegration Machining, the process is still considered spark erosion, hence the name spark eroder. Part of this name has to do with the sparks that are created by this process, erosion obviously refers to the process which allows broken tooling to be removed with these machines. The term spark erosion is more popular in countries like England and India. This term is used because the principal is more commonly understood under this name than “metal disintegrator”.

In fact, Electro Arc used the term to refer to our own machines between 2008 and 2018. Uni-Tek had a patent on the name “Tap-Zapper” which became associated with many of these machines as well. Electro Arc kept the patent for a short time but also used the term to describe many of our AC metal disintegrating machines. We find that these terms can be confusing and have made an effort to clarify each machine’s model and its features to help you choose the best metal disintegrator for your application.