5 Steps to Choose the Machine You Need to Remove Broken Bolts

Our broken bolt, drill, and tap removal technology is the most cost-effective and precise method available in the market. Patented in 1942, AC metal disintegrators were made and distributed exclusively by Electro Arc for years before competitors entered the market. Electro Arc purchased Uni-Tek in 2004 and began making and distributing DC machines as well including the Bolt Eater. Electro Arc metal disintegration machines have been built in Michigan since the company began in 1947. These machines are known for their long-lasting design and easy-to-use configuration, allowing companies to apply the technology across industries.

See the Bolt Eater in Action:

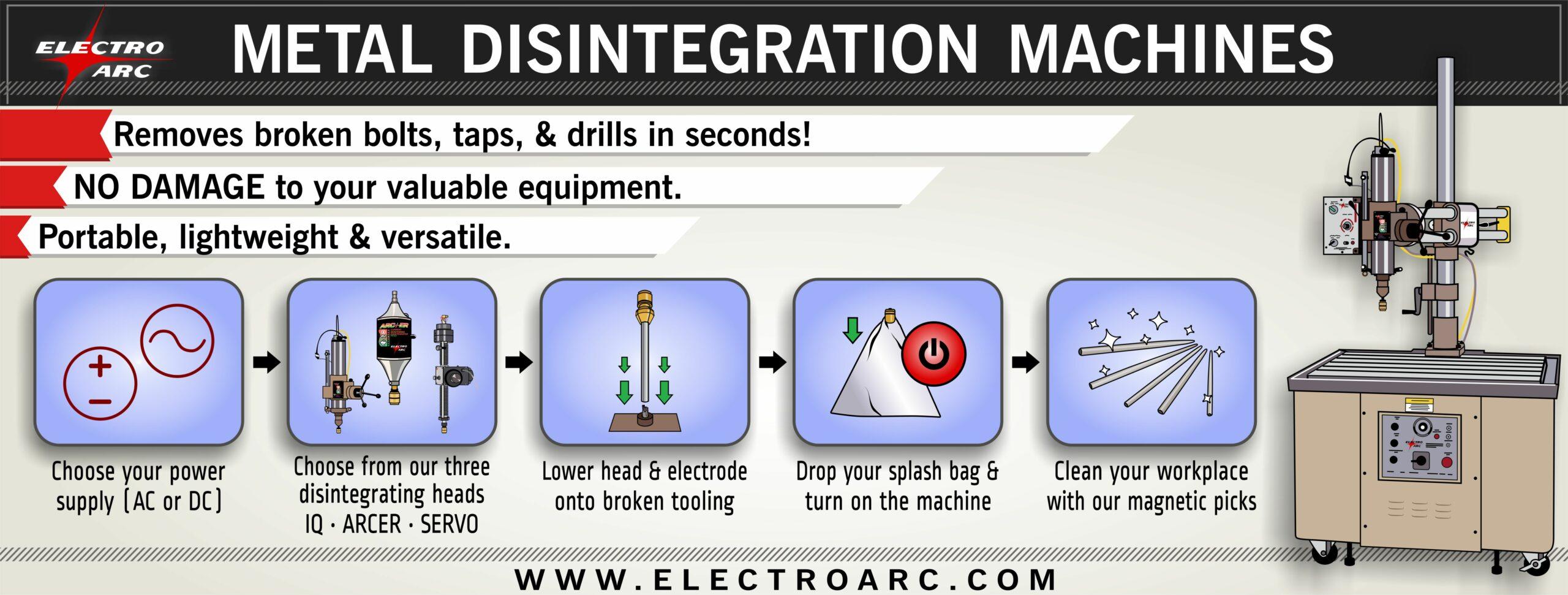

You can use Electro Arc metal disintegration machines to quickly and easily remove the broken-off tap, drill, and or bolt without damaging your valuable equipment. In the infographic above, you can see the details of our precise spark erosion process. Please refer to the following recommendations to choose the right metal disintegrator for your needs.

How to choose the right metal disintegrator for your application:

Step 1. Do you need an AC or DC power supply?

Both AC and DC machines run 110 to 600 volts to vibrate AC machines make and break 50 or 60 times per second, while DC machines are at 120 times per second. DC power can maintain higher arc levels and sustain a larger arc. With DC machines you can use larger electrodes like square or hex-shaped carbon to drill faster and make larger holes.

Step 2. Next, which disintegrating head do you need? IQ, Servo, or Arc-er.

You can use the Arc-er head with our portable metal disintegrators and you can use it directly with machines like a Bridgeport. The IQ head provides faster-cutting speed and can be used with larger electrodes. You will receive a Servo head with our DC machines.

Step 3. Do you want a Portable or Table top machine?

Portable machines are great for on-site application. If you need to take the metal disintegrator to the part, a portable metal disintegrator is for you. Off-road vehicle repair, mining operations, submarines, and repairs on the line are some great examples that would benefit from a portable machine.

You will want a tabletop machine if you are working on parts that can be taken to the machine for disintegration. We offer tabletops ranging in sizes and can create custom table tops if needed.

Step 4.

Which electrode do you need?

We offer electrodes made of graphite, copper, and molybdenum. Depending on the hardness of your piece, you will want to choose the appropriate electrode. Please refer to our sizing charts to choose the best one for your needs.

-

Metric Starter Set$532.50

Metric Starter Set$532.50 -

Standard Starter Set$532.50

Standard Starter Set$532.50

Step 5. What kind of material are you working with?

If you are working with carbide, you will want to choose a machine with “C” in the model number such as our 2-SEC which is a more compact tabletop machine offering the durability and power to disintegrate carbide.