Electro Arc Metal Disintegrators made in Michigan since 1947

Electro Arc is the original manufacturer of Metal Disintegrators based in Michigan. The company’s founder, Harold Stark patented the AC metal disintegration process in 1942 and opened Electro Arc’s doors in 1947. Stillion Industries purchased Electro Arc in 2019 and carries on the quality name that Electro Arc metal disintegrators have become synonymous with.

Electro Arc Metal Disintegrators Last a Lifetime

You can see one of Electro Arc’s original paper promotions above, featuring the following models:

Model 2-S – Still one of our most popular portable models! This basic metal disintegrator now features our Arc-er Head and portable design which make it perfect for use in small shops.

1-S (See below) – The model 1-S was the largest table top metal disintegrator offered by Electro Arc initially.

2-SA – The model 2-SA was one of the first tabletop metal disintegrators offered by Electro Arc. This self-contained unit is great for high production plants and tool shops.

3-S – The model 3-S originally offered with no built-in coolant tank offers great portability for use in confined spaces.

Not shown on this flyer, the Carbide Impregnator was another flagship product Electro Arc was known for between the 1940s and 1970s. Electro Arc is the original and best manufacturer of metal disintegrators in the world. Our machines are known for their durability and long-lasting design. Now among over 40 configurations available, we are confident you will find an Electro Arc metal disintegrator is still the best value for your application!

Over 75 Years of Michigan Manufacturing

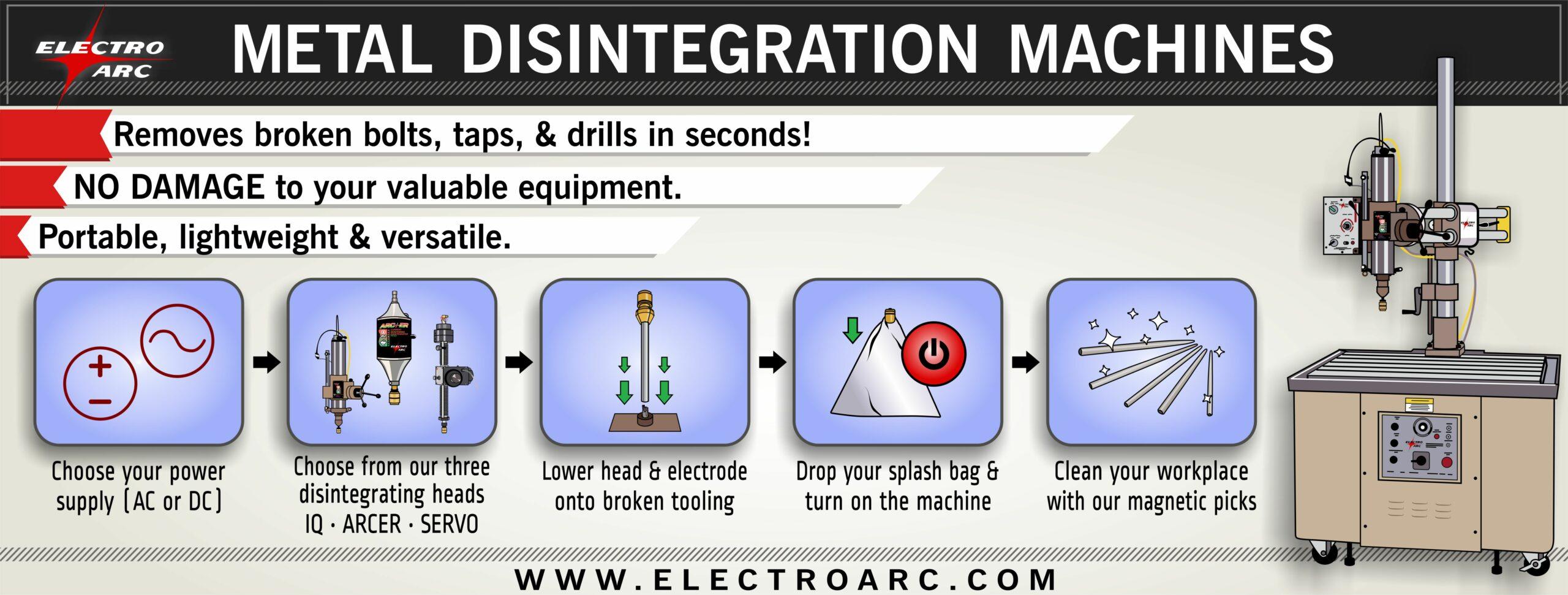

As you can see, the original disintegrating head is different than our current Arc-er, IQ, and Servo disintegrating heads. The features of Electro Arc metal disintegrators are the same great features allowing anyone to use our machines. Electro Arc Metal Disintegrators have castors, the choice of AC or DC, and portable or tabletop, including the option to order a custom table top size. Most models allow you to choose your KVA power rating. Additional features include support options, head options, remote start/stop, and more!

In 2004, Electro Arc purchased Uni-Tek and integrated DC metal disintegrators into our product line. Our most powerful machine, the Bolt Eater represents the heavy-duty application of metal disintegration with both portability and the power to remove large bolts!

Stillion Industries is proud to carry on the Electro Arc Metal Disintegrator legacy in Dexter Michigan! We continue to improve the metal disintegrator design and offer repair and refurbishing services for old machines. Learn more about Electro Arc’s history.