How to Remove a Broken Tap Quickly

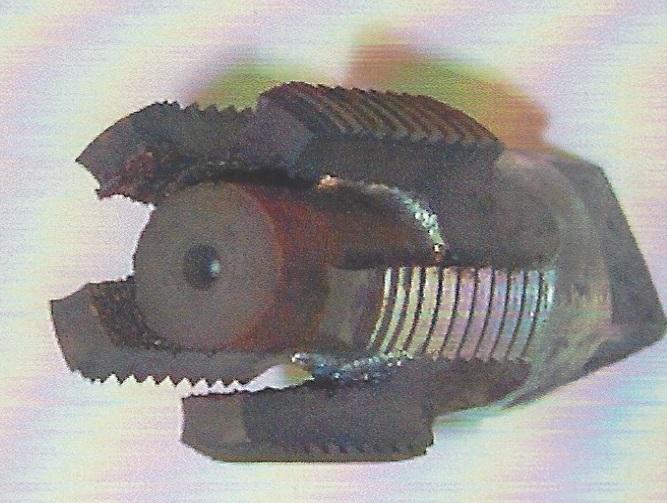

Electro Arc’s 3-S portable metal disintegrator is featured below. You do not need dielectric fluid to use Electro Arc machines, just coolant. The 3-S is easy on your pockets and convenient for you to use. Our metal disintegrators remove broken taps and drills without damage or coming into contact with the part. You can also use an Arc-er Head with other machine tools like the drill press in the video below:

What is a metal disintegrator?

You have probably heard a metal disintegrator referred to by many names including; tap extractor MDM machine, tap burner, tap zapper, and spark eroder. You can use these metal disintegration machines to remove broken bolts, broken taps, and broken drills without damaging your part. Cheap alternatives are available but can cause more damage or break easily. With an Electro Arc metal disintegrator, you get the precision, speed, and value without the headache of replacing parts on expensive equipment.

Broken tap removal service

You may experience broken taps in any situation, even when drilling and tapping a riffle, the risk of a broken tap is present. It may be tempting to use a simple cheap product like ex-out or Tap Magic, but as many of you know, this often makes the problem worse.

When you are working with broken taps it is important to remember that the center part is solid. Meaning the broken tap can be broken and essentially removed. Taps with a thread size smaller than M12 should be removed by breaking the center. In some cases, your tap will have a very large thread. If this is the case we advise that you divide it into halves for removal. You do not have to apply the electrode to the largest depth. When it reaches the desired depth just turn up the Arc-er head and begin to remove the debris. You can then continue the process of disintegration with your electrode. The power of a metal disintegrator is established by creating a series of electric arcs or discharges that erode the broken metals into smaller particles.

This produces sparks that move between the broken piece and the electrode cutting through the broken machine part. A puddle is created by the spark (also known as the hot plasma) as a result of the workpiece being melted by the electrical discharge produced by the electrode. The small amount of dielectric is vaporized which creates bubbles around the spark.

It is important to keep your work area clean. A slower removal rate increases the rate of tear which is related to the rate of removal. The head is located in the flush area which helps to speed up the time for metal removal. The result of the removal also affects the size of the spark. Big and long sparks lead to a bigger depth and a rougher surface. For a finer finish, smaller sparks, a higher wear rate, and low removal rate are required. There are copper alloys that have been designed to maximize the process of spark eroding and offer better wear resistance and improved machinability.